Continuous improvement

Lean construction is the never-ending drive for perfection. It centers on continuous improvement and respect for people. Our clients and partners should expect to receive exactly what they require, when they require it, and with the highest degree of quality. Read our blog on continous improvement.

What is Lean?

What is Lean?

2-Second Lean

2-Second Lean

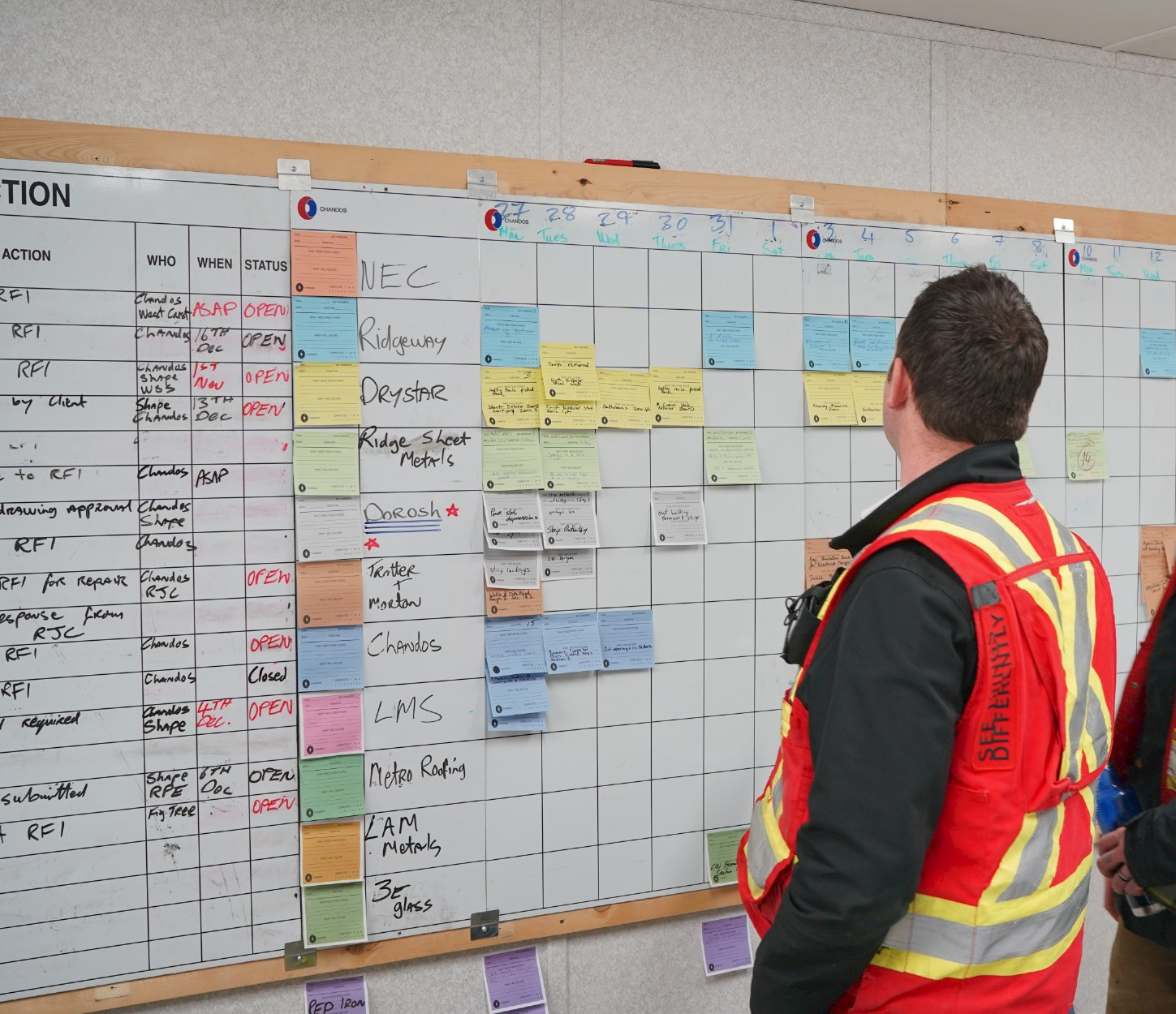

Last Planner

Last Planner

Roxy Theatre Restoration | $9.4M

Roxy Theatre Restoration | $9.4M

Crimson Villas | $22.8M

Crimson Villas | $22.8M

Advanced Nuclear Materials Research Center

Advanced Nuclear Materials Research Center