Efficient builds

Our teams can implement innovative processes that offer a more accurate exchange of information, improve coordination, and increase productivity on projects. This results in thorough and efficient builds.

Our team of experts are waiting, simply fill out the form below and we’ll be in touch.

We use the latest technology to solve potential issues early on, and eliminate extra costs and downtime.

Our team of experts are waiting, simply fill out the form below and we’ll be in touch.

Our teams can implement innovative processes that offer a more accurate exchange of information, improve coordination, and increase productivity on projects. This results in thorough and efficient builds.

Our VDC Team

Our VDC Team

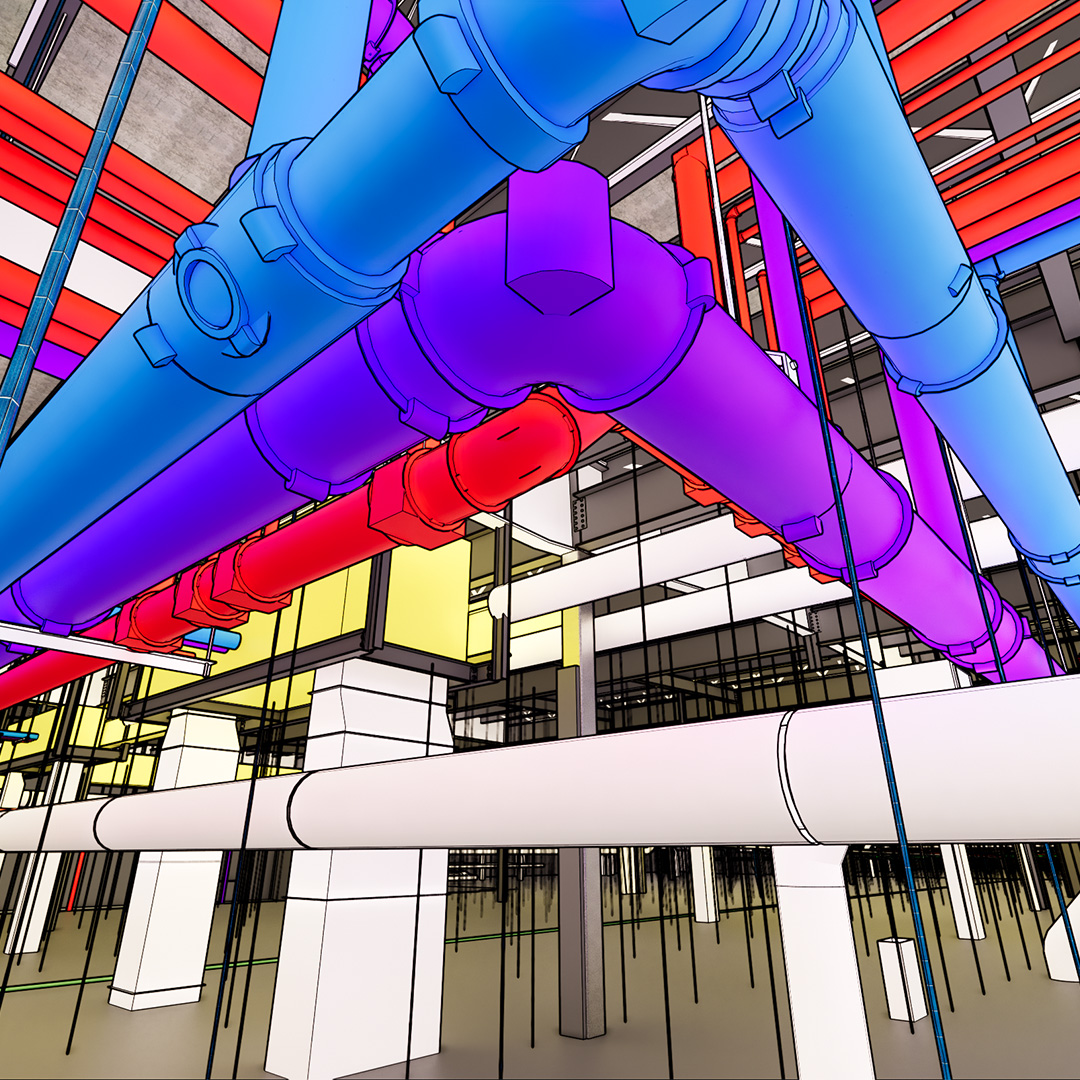

Our virtual design and construction (VDC) team creates information models of the built environment. This provides stakeholders with a clear visual of how a project will develop sequentially. Being able to prototype at an early stage avoids wasteful and costly rework.

What is BIM?

What is BIM?

Building information modelling (BIM) is a platform that builds an object with associated information. VDC uses BIM models to plan the construction process from beginning to end. No matter the size of a project, BIM helps us deliver durable buildings more quickly with savings passed on to customers.

Digital Pre-Fabrication

Digital Pre-Fabrication

This innovative tool uses digitized information to facilitate manufacturing of materials or assemblies - such as, sheet metal fabrication, structural steel fabrication, pipe cutting, and prototyping. The process saves time; reduces waste; increases productivity and safety; and accommodates design changes.

By using innovative technology, we've been able to achieve significant reductions in the amount of carbon being emitted on jobsites. And work towards a net-zero future. Read More.

Having instant access to project progress and collaborating on virtual models to test ideas assures teams stay on track and choose the best solution possible.

Calgary Climbing Centre | 24,500 sq. ft. | $7.5M

Calgary Climbing Centre | 24,500 sq. ft. | $7.5M

BIM helped us discover HVAC interferences with the structural and architectural components. For example, the model revealed some ductwork running into a climbing wall - a problem best addressed before the incident was discovered in the field. Clash detection also resolved several conflicts, saving significant dollars and calendar days in rework.

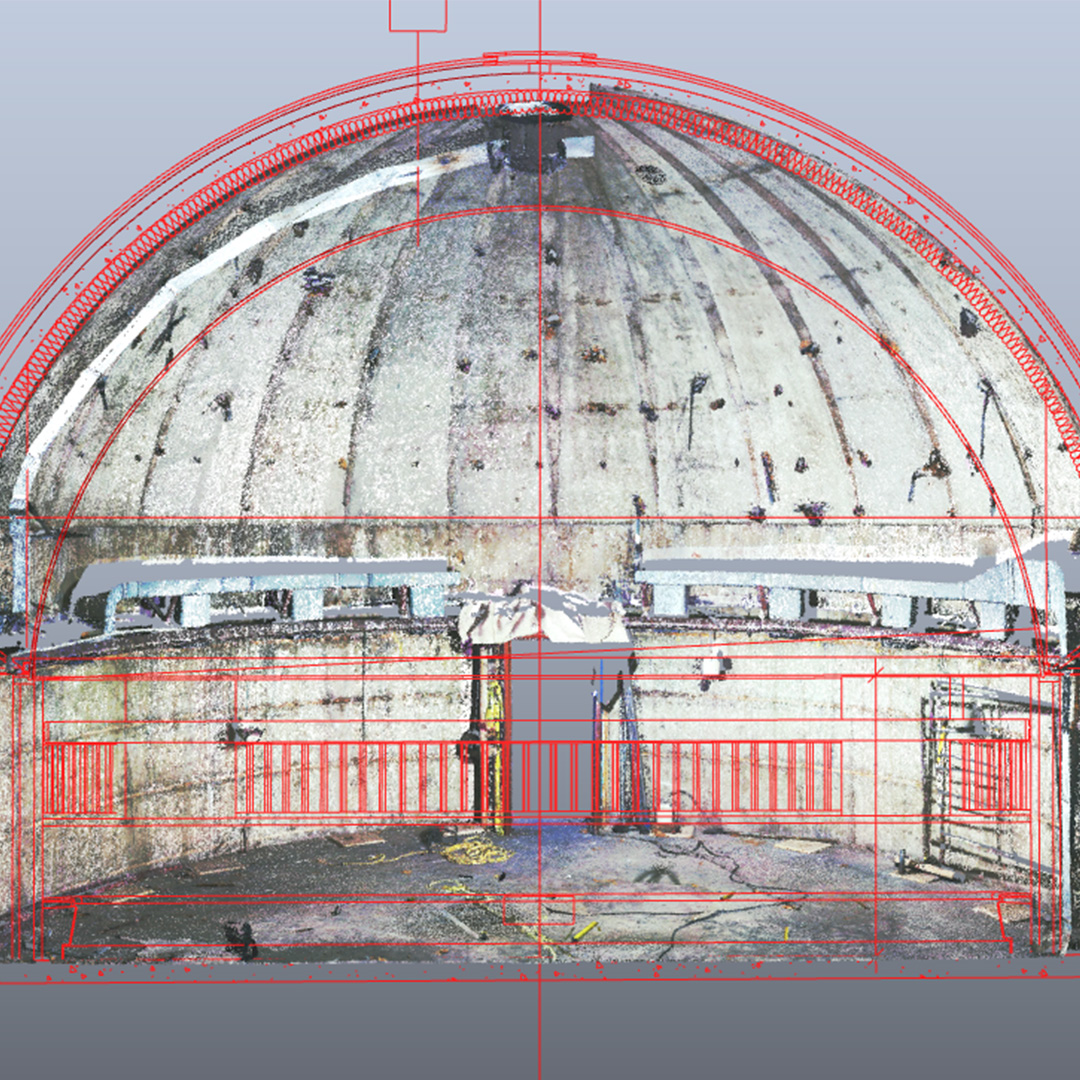

SFU Stadium Upgrades | 31,645 sq. ft. | $16.9M

SFU Stadium Upgrades | 31,645 sq. ft. | $16.9M

Using BIM during the testing stage, helped us discover mechanical, electrical and plumbing system interferences. The model revealed that the shaft opening was not big enough to accommodate all HVAC and fire protection systems. Bringing the issues to attention early in the design stage, provided the team with ample time to come up with effective solutions.

Barrie-Simcoe Emergency Services | 190,000 sq. ft. | $86.5M

Barrie-Simcoe Emergency Services | 190,000 sq. ft. | $86.5M

During this project our team worked towards a 4D/5D model with the ultimate goal of handing over high-quality as-builts through the use of laser scanning and a digital maintenance manual to assist the client with future operations of the building.